Discover the Advanced 160 Watt Walkable Marine Solar Panel

Discover the outstanding performance of our semi-rigid 160-watt walkable marine solar panel, designed specifically for Mercedes-Benz Sprinter, Ford Transit and Ram Promaster vans. These are NOT your typical flexible solar panels! With premium HJT solar cells, these panels offer good efficiency, featuring a durable backing and ETFE laminate non-skid surface that is designed to be walked on. For the best solar cells and efficiency look at our 160w sunpower panel. Ideal for van roofs, they redefine versatility in solar energy solutions.

The panel's advanced HJT technology delivers up to 6-14% more energy than standard monocrystalline cells. There is no glass and no aluminum frame so these panels are considerably lighter than rigid panels but heavier and stiffer than typical flexible panels. They can be bent slightly to match up with the underlying surface, about 5%. The white backing is better at dissipating heat. For maximum space utilization and functionality on your van roof, combine these walkable solar panels with our modular deck panels for the ultimate solution.

Key Features:

- Exceptional Durability: Ensuring durability and reliability even in harsh marine environments.

- Premium A-Grade HJT Solar Cells: Designed for maximum efficiency and performance, even in partial sunlight conditions.

- Ideal for Various Applications: Perfect for rigid surfaces such as van roofs, RV roofs, or sailboats.

- Lightweight: Weighing only 11.8 pounds, these panels can be bent slightly to match the underlying surface, offering flexibility in installation.

- Manufacturer's Warranty: Enjoy a 1-year warranty at 80% efficiency, plus 4 years prorated.

Check out our full collection of Walkable Marine Solar Panels:

- 65 Watt Walkable Marine Solar Panel

- 100 Watt Walkable Marine Solar Panel

- 165 Watt Walkable Marine Solar Panel

- 175 Watt Walkable Marine Solar Panel

- 200 Watt Walkable Marine Solar Panel

Specifications:

- Panel Type: HJT solar cells

- Rated Power: 160 Watts

- Manufacturer's Warranty: 1 Year @ 80% + 4 Years Prorated

- Dimensions: ~26.4" X 47.7"

- Weight: 11.8 pounds

- Output Connections: 6-foot Duplex Cable 3/8" OD

- Peak Power Voltage (Vmpp): 22.3 Volts

- Peak Power Amps (Impp): 7 Amps

- Open Circuit Voltage (Voc): 25.7 Volts

- Short Circuit Current (Isc): 7.4 Amps

- Cell Conversion Efficiency: 24.2%

Installation:

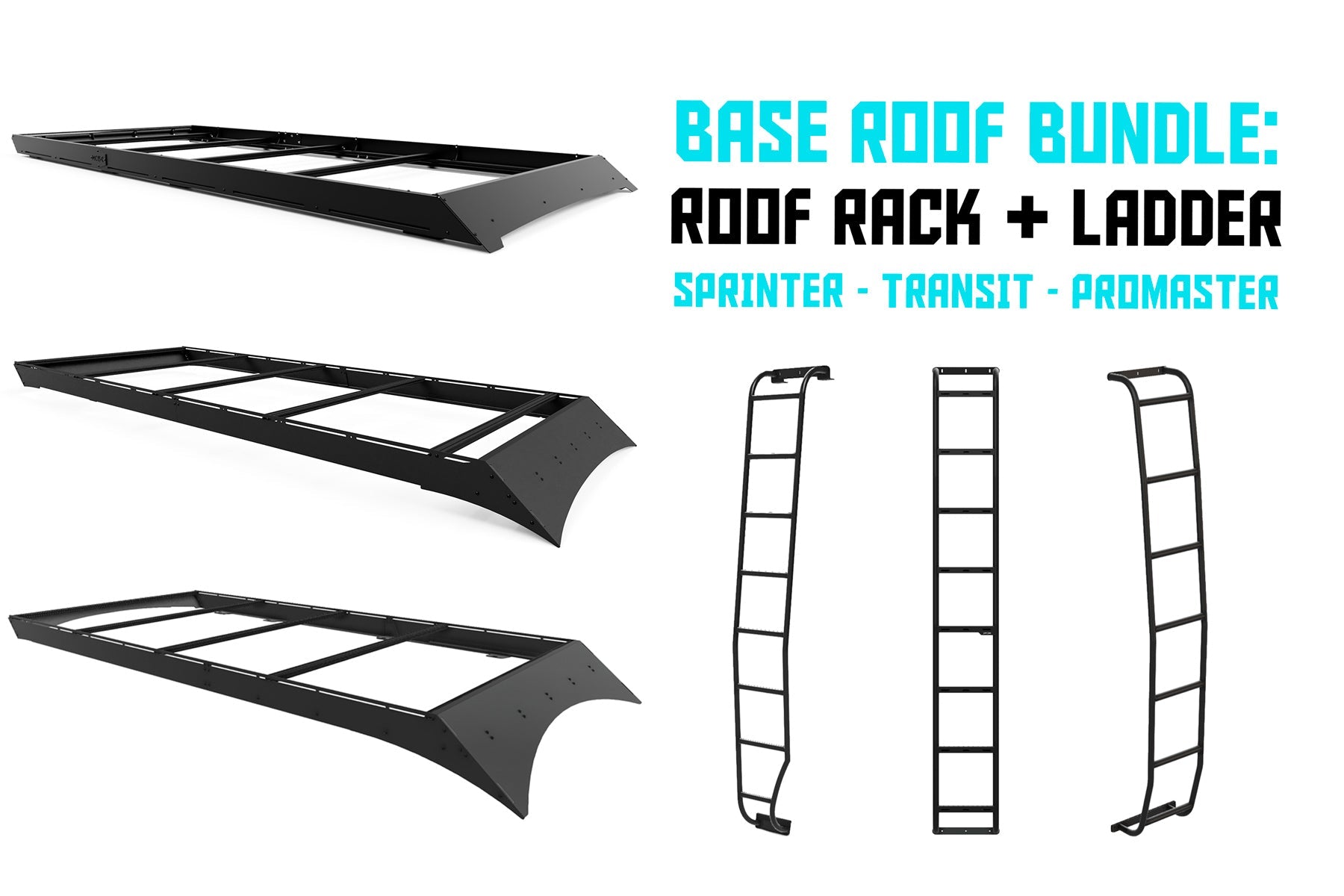

For Sprinter Stealth+ Roof Rack or Transit Stealth+ Roof Rack with Deck Panels: We recommend rivnuts (must be able to span .136" material thickness) with our walkable solar washers on all 4 corners (medium threadlocker) in addition to 'J' channels and 'H' channels on every edge of each panel.

Contact us if you have any questions or need assistance with your installation. These panels can be paired effectively with Orion's Modular Roof Deck Panels for optimal space utilization and function on van roofs. For more details, you can check out the Modular Roof Deck Panels page.

FAQs for 160W Walkable Monocrystalline Marine Solar Panel

The 160W walkable marine solar panel features exceptional durability, premium A-Grade HJT solar cells, and a semi-rigid design. It has a durable backing, ETFE laminate non-skid surface, and is lightweight, making it ideal for van roofs, RV roofs, or sailboats.

Yes, the panels have an ETFE laminate non-skid surface that makes them walkable without damaging the solar cells.

These panels are perfect for rigid surfaces such as van roofs, RV roofs, or sailboats.

The 160W solar panel measures 26.4" x 47.7" and weighs 11.8 pounds.

The panel uses Class A Monocrystalline HJT cells, known for their high efficiency and performance.

The cell conversion efficiency is 24.2%.

The manufacturer provides a 1-year warranty at 80% efficiency, plus a 4-year prorated warranty.

Kind of, the panels are semi-rigid and can be bent approximately 5% to match the underlying surface, offering flexibility in installation.

The panels are only available with a white backing as the performance is better for all van applications.

For Sprinter Stealth+ or Transit Stealth+ Roof Racks with Deck Panels: Use Rivnuts with our corner washers on all four corners and apply medium threadlocker. Use 'J' and 'H' channels on all edges of the panels in addition to the corner hardware.

No, hardware is not included. Recommendations for mounting hardware are provided in the product description.

Rated Power: 160 Watts

Peak Power Voltage (Vmpp): 22.3 Volts

Peak Power Amps (Impp): 7 Amps

Open Circuit Voltage (Voc): 25.7 Volts

Short Circuit Current (Isc): 7.4 Amps

Yes, you can contact us for any questions or assistance with your installation.

Please visit our website to explore the full range of walkable solar panels.